Transforming Semiconductor Filtration

Often referred to as “the brains behind modern electronics”, semiconductors are the foundational force driving countless technological innovations, powering everything from cutting-edge smartphones and quantum computers to medical devices, automotive systems, industrial machinery, advanced military and space technology, and more. These tiny chips are made from materials with electrical conductivity between that of conductors and insulators, allowing precise control of electrical currents. By altering their properties through processes like doping, semiconductors can function as switches, amplifiers, and energy converters. This adaptability makes them crucial in a wide range of applications, including computing, communication, power management, sensing technologies, and more, across many industries.

Industries Relying on Semiconductors

And Many More!

As the demand for faster, more efficient, and more powerful chips continues to grow across industries, the semiconductor sector is expanding rapidly. According to the Semiconductor Industry Association (SIA), nearly 1 trillion semiconductors were sold globally in 2023, that is, more than 100 chips for every person on earth. The SIA states that the semiconductor market continues to grow substantially. In fact, the industry’s sales hit $57.8 billion in November 2024, translating to a 20.7% growth in comparison to the market standing at $47.9 billion in November of 2023. McKinsey’s analysis based on a range of macroeconomic assumptions projects that the industry will surpass $1 trillion by the end of the decade.

Nevertheless, as the semiconductor industry continues to expand to meet the growing demand for smarter, faster, and more energy-efficient devices, it also brings forth significant environmental challenges. Today, the semiconductor industry remains one of the most energy and resource-intensive sectors with a significant carbon footprint, accounting for almost 75% of the total CO₂ emissions in connection with electronic communication devices; that is significantly more than the emissions from the power consumption of the devices during their lifespans.

A major driver of CO₂ emissions in this industry is the widespread incineration of chemicals, particularly solvents, after a single use. Solvents are essential at nearly every stage of manufacturing, serving as chemical carriers, cleaners, and processing agents. They enable the dissolution and deposition of materials, control reaction conditions, and remove impurities that could compromise circuit performance, all of which are critical for the precision required in advanced chip production. Given that even the slightest contamination can cause defects, these solvents must be of extremely high purity. As a result, the industry often prioritizes incineration over solvent recovery, overlooking the potential of solvent recycling systems. However, these solvents are valuable resources that can be recovered and reintegrated into the same or other industrial processes, significantly reducing waste, emissions, and resource depletion.

How Does SepPure Revolutionize Solvent Reuse for Semiconductor Filtration?

SepPure Technologies enables the efficient recovery of high-purity solvents through its advanced semiconductor filtration technology, providing a sustainable alternative to incineration. Utilizing its cutting-edge Organic Solvent Nanofiltration (OSN) membrane technology, SepPure enables the separation and purification of solvents at the molecular level without excessive heat or chemicals. This energy-efficient approach preserves solvent quality, enabling their reuse in the same or other industrial applications while minimizing waste and emissions. By integrating solvent recovery into the semiconductor manufacturing process, SepPure helps the industry lower its operational costs, reduce its carbon footprint, and advance toward a more circular and sustainable chemical supply chain.

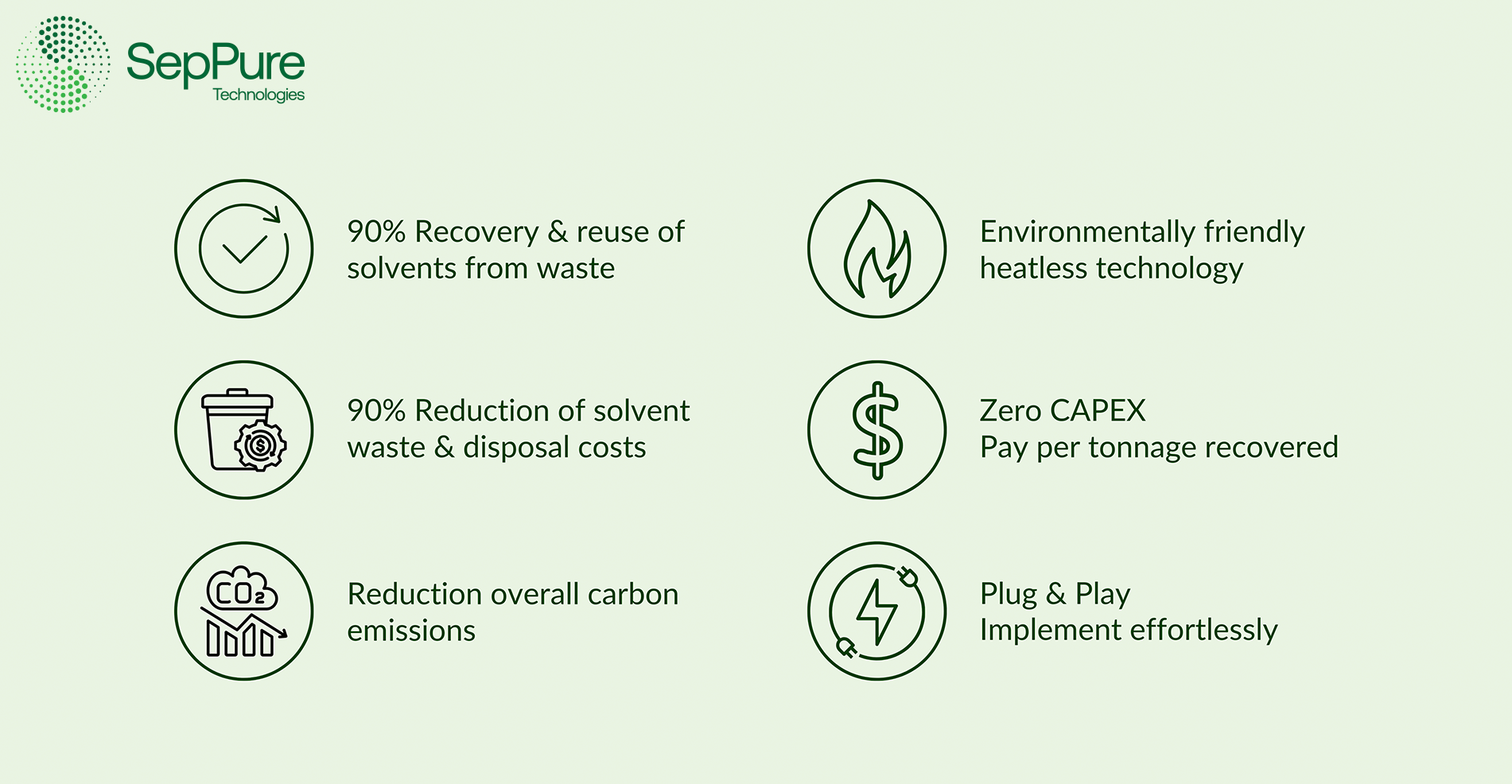

1. 90% Recovery & Reuse of Solvents

SepPure’s advanced nanofiltration technology enables the recovery and reuse of 90% of spent solvents, achieving technical-grade purity exceeding 99.9%. This enables the solvents to be cascaded into other processes and industries, significantly reducing environmental impact compared to using fresh solvents.

2. 90% Reduction of Solvent Waste & Disposal Costs

By significantly reducing the volume of waste solvents, SepPure minimizes disposal costs and lowers the environmental challenges associated with waste management.

3. 90% reduction in energy consumption

By taking on the heavy lifting of bulk solvent recovery, SepPure makes subsequent polishing steps in the semiconductor manufacturing process up to 90% less energy intensive, making the overall process greener.

4. Reducing Overall GHG Emissions

By eliminating the need to incinerate solvents and reducing reliance on energy-intensive processes for chemical separation, such as distillation, SepPure’s solution cuts greenhouse gas emissions, contributing to more sustainable industrial processes.

5. Environmentally Friendly Heatless Technology

Unlike traditional methods that rely on heat, SepPure’s solution is pressure-driven. This not only saves substantial energy, but it also prevents thermal degradation of solvents.

6. Zero-CAPEX Model

SepPure offers a cost-effective, zero-CAPEX model, allowing industries to adopt its solvent recovery technology without significant upfront investment, making sustainability accessible and profitable.

7. Easy Plug & Play System

SepPure streamlines solvent recovery by offering a user-friendly approach: simply fill the system with waste solvent, press a button to start the purification process, and retrieve the high-purity solvent, ready for reuse.

Why Choose SepPure’s Solution for Semiconductor Filtration?

SepPure’s RE(SOLV)® Solvent Recovery System represents a breakthrough, standing as the most advanced solvent recycling technology in the market. Engineered to be chemically resistant, it withstands a wide range of solvents, ensuring efficient and reliable treatment of even the most chemically challenging substances.

| High Packing Density | High Flux Formulation | Chemically Resistant |

|---|---|---|

| Achieve greater performance with optimized packing density that boosts filtration capacity. | Maximize throughput with superior flux efficiency for quicker processes. | Engineered to endure the toughest solvents without degradation. |

Interested to learn more?

Frequently Asked Questions (FAQs) About SepPure’s Solvent Recycling for Semiconductor Filtration

-

Solvents are of vital importance in the semiconductor manufacturing process, serving as chemical carriers, cleaners, and processing agents to ensure the precision and reliability of microelectronic components. They enable the dissolution and deposition of materials, control reaction conditions, and remove impurities that could compromise circuit performance. Their role is particularly crucial in achieving the accuracy required for advanced chip production, where even the slightest contamination can lead to defects.

-

Some of the primary challenges associated with solvent use in the semiconductor industry include high cost of procuring ultra-pure solvents, substantial solvent use, significant waste generation due to strict contamination tolerance, and improper disposal of waste solvents, all of which lead to increasing environmental and economic concerns.

-

SepPure Technologies enables sustainable recovery of solvents with purity levels exceeding 99.9%. This approach not only makes the subsequent polishing steps less energy intensive, but it allows the solvents to be cascaded into other processes and industries, significantly reducing environmental impact compared to the use of fresh solvents.

-

The semiconductor industry heavily relies on solvents in nearly every stage of the manufacturing processes. However, due to extremely high purity requirements, most solvents are disposed after a single use through incineration. SepPure enables the sustainable recovery of these solvents, allowing them to be reintegrated into the same or other industrial processes.

-

By adapting SepPure’s solution, semiconductor manufacturers can reduce the cost of raw materials and waste management by up to 90%, thereby lowering the overall operational cost of the manufacturing process.

-

SepPure’s solvent recovery solution is powered by the advanced technology of its revolutionary GreenMem® Organic Solvent Nanofiltration membrane. These chemical-resistant hollow fiber membranes feature pores smaller than 1 nanometer in size, thereby allowing very precise separation of chemicals at the molecular level.

-

The traditional solvent recovery methods, such as distillation, are extremely energy intensive. SepPure's innovative heatless technology offers an environmentally-friendly approach compared to conventional models, making it both energy-efficient and cost-effective.

-

SepPure Technologies is the only company in the world that specializes in Organic Solvent Nanofiltration (OSN) membrane solutions for polar and polar-aprotic solvents. Given that the semiconductor industry relies on a variety of solvents, including toxic chemicals, SepPure offers the best and most robust chemical-resistant OSN membranes for this industry in the market.

-

SepPure offers a zero-CAPEX model, allowing businesses to pay based on the tonnage of solvent recovered. This eliminates the need for significant upfront investment, enabling seamless implementation.

-

SepPure streamlines solvent recovery by offering a user-friendly approach: simply fill the system with waste solvent, press a button to start the purification process, and retrieve the high-purity solvent, ready for reuse.

-

Yes, SepPure offers comprehensive support, including technical assistance, system maintenance, and optimization guidance to ensure peak performance and maximum efficiency.