Vegetable Oil Refining Process: From Raw to Refined

A typical vegetable oil refinery emits a median of 3.81 kg of CO2e per kg of refined oil, according to the University of Nottingham. This significant level of greenhouse gas (GHG) emissions is observed across various oil crops such as palm, soybean, rapeseed, and sunflower, produced by over 6,000 producers in more than 40 countries, collectively representing over 71% of global vegetable oil production. The carbon footprint, however, varies by crop: rapeseed oil has a median emission of 2.49 kg CO2e per kg of refined oil, while soybean oil emissions can reach up to 4.25 kg CO2e per kg.

The oil refining process is particularly energy-intensive, relying heavily on fossil fuels through conventional methods like thermal extraction and chemical refining. To produce just one tonne of edible oil, between 4 to 10 tonnes of solvents are required to be heated, vaporized, and condensed using traditional distillation methods. According to the United States Department of Agriculture (USDA), global production of vegetable oils is forecast to reach 234.5 million tonnes in the 2025/26 marketing year, fully covering a projected demand of 228.9 million tonnes. As global demand for vegetable oil continues to grow, the economic and environmental challenges surrounding conventional refining methods are becoming increasingly critical. This article examines the edible oil refining process and highlights pathways for transitioning toward more sustainable practices.

What is the Vegetable Oil Refining Process?

The oil refining process includes a multi-step procedure designed to remove impurities and undesirable components from crude oil, producing safe, high-quality products for consumption. Traditional oil refining methods rely on thermal and chemical treatments, often consuming large amounts of energy and solvents. However, modern advancements such as membrane-based separations offer more sustainable and cost-effective alternatives.

What is the Process of Vegetable Oil Refining?

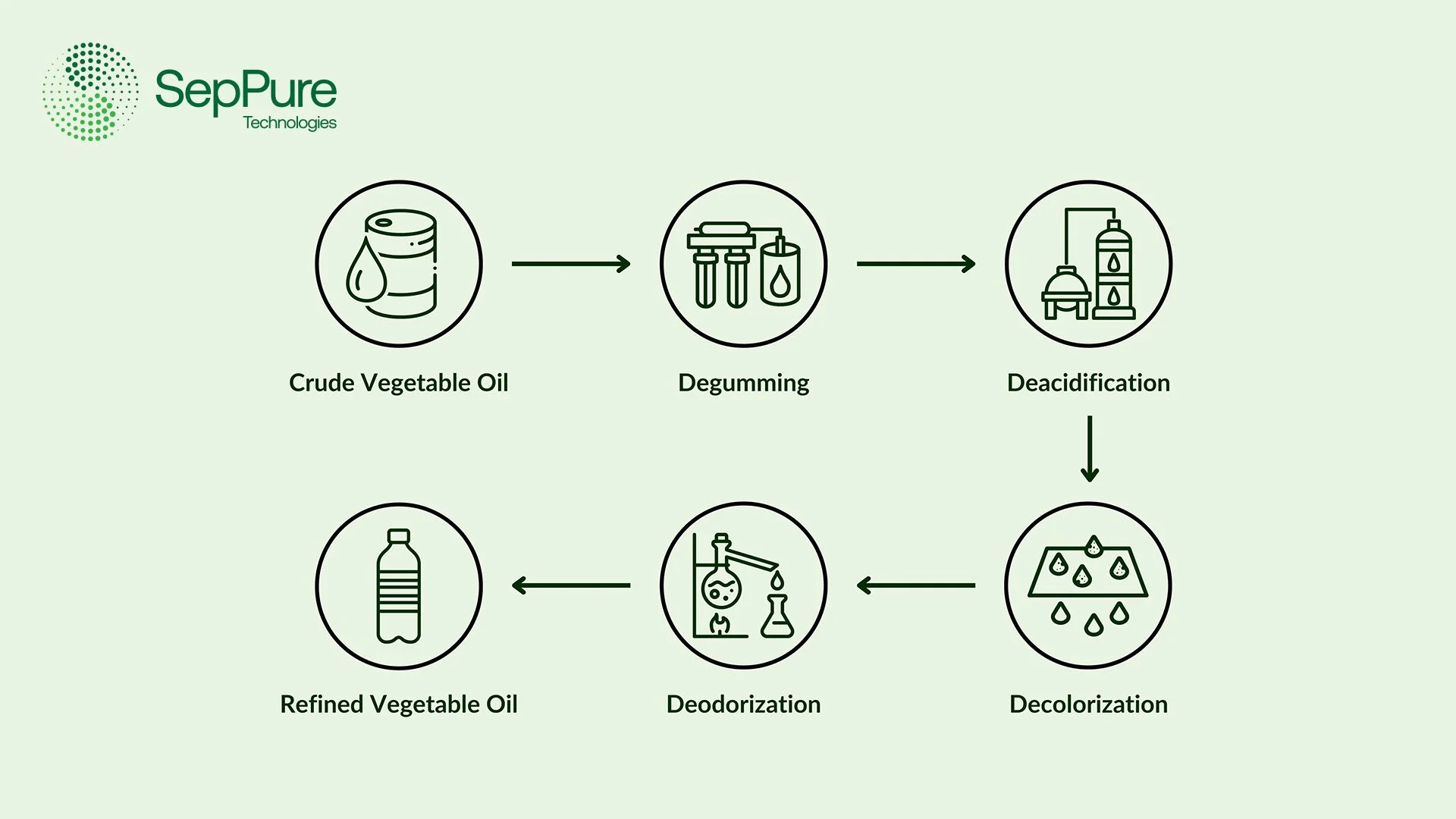

The oil refining process transforms crude extracts into pure, stable, and food-grade oils suitable for consumption. There are several key stages in edible oil processing at the vegetable oil refinery. A brief overview of these stages is provided below:

Degumming

The first step involves removing phospholipids (or gums) by treating the crude oil with water or acid, causing gums to precipitate and be separated from the oil.Deacidification (Neutralization)

In this stage, free fatty acids (FFA) are neutralized using an alkali solution, typically sodium hydroxide. This reaction forms soapstocks, which are subsequently separated from the oil. The process improves oxidative stability and extends shelf life.Decolorization (Bleaching)

To remove unwanted pigments such as chlorophyll and carotenoids, the oil is treated with activated bleaching earth under vacuum conditions. This results in a clearer, lighter-colored oil.Deodorization

Here, volatile compounds responsible for undesirable odors and flavors are removed by steam distillation under high vacuum at elevated temperatures. This step ensures a neutral odorless oil, suitable for consumption.Winterization (Dewaxing, if applicable)

Oils prone to wax formation, such as sunflower or corn oil, undergo cooling to crystallize and remove waxes. This prevents cloudiness and ensures clarity at lower temperatures.

As global demand for vegetable oil increases, the economic and environmental challenges intensify. The Organization for Economic Cooperation and Development estimates the vegetable oil demand to increase by 20% by 2023!

A Game-Changing Solution: OSN Membrane Technology

Our Organic Solvent Nanofiltration (OSN) membrane technology offers a transformative, energy-efficient alternative for the vegetable oil processing and refining industry. By adopting OSN membrane technology, producers can dramatically lower their carbon footprint, reduce energy costs, and contribute to a more sustainable future. With the global demand for vegetable oil on the rise, adopting advanced technologies like Organic Solvent Nanofiltration (OSN) membranes is no longer a choice, but a necessity for achieving production targets while upholding environmental responsibility.

GreenMem® Solutions for Vegetable Oil Processing

Solvent Recovery

Solvents are used for oil extraction, fractionation, and potentially other downstream processes. Towards the end of each process, solvents are separated from products through energy-intensive distillation or evaporation processes. Our OSN membranes can do 90% of the job wihtout the use of heat, leaving existing distillation unit to handle only the remaining 10% of the solvent!

Fractionation

Fractionation involves controlled cooling of the oil, thereby inducing a fractional crystallization. The remaining olein is then separated from stearin, which can then be used in food ingredients or other downstream applications. Our OSN membranes offer a more efficient separation method to the energy-intensive means of centrifugation, by selectively separating impurities at lower pressures.

Deacidification

Our Organic Solvent Nanofiltration (OSN) membrane deacidification technology enables molecular-level removal of free fatty acids (FFA) as an alternative to using caustic and steam. With this approach, vegetable oil producers can cut energy demand by 50%, minimize loss of natural oil, and eliminate significant generation of wastewater.

And Much More!

Powered by GreenMem®, our DE(SOLV)® offers a transformative solution to the vegetable oil refining industry, making the overall process cleaner and more sustainable.

Frequently Asked Questions (FAQs) About Vegetable Oil Refining

-

Refining is necessary, because crude oil contains impurities that affect the quality, taste, and safety of the oil. A vegetable oil refinery removes these impurities to prevent off-flavors, extend shelf life, and eliminate health risks. This refining process ensures that the oil meets strict food and quality standards.

-

The vegetable oil refining process involves the use of several chemicals to remove impurities and improve the quality of oil. Common chemicals used include phosphoric or citric acid in the degumming process to remove phospholipids, sodium hydroxide for neutralization, which helps remove free fatty acids, and bleaching earth during decolorization (or bleaching) to remove unwanted pigments such as chlorophyll and carotenoids.

-

Vegetable oils are extracted using solvents that can affectively mix with their non-polar nature. Non-polar or slightly polar solvents such as hexane, ethanol, acetone, or chloroform are the typical choices. However, each solvent does come with its particular trade-offs in terms of energy use, safety, and environmental impact. Thus, advances in energy-efficient alternatives like Organic Solvent Nanofiltration (OSN) membranes are gaining traction.

-

The vegetable oil refining process involves several key steps to ensure the oil is of high quality and safe for consumption. These steps include:

Degumming: The first step in the vegetable oil refinery is degumming, which involves removal of phospholipids (gums) from the crude oil.

Neutralization: Elimination of free fatty acids using an alkaline substance.

Bleaching: Removal of colour pigments, oxidation products, and other impurities using bleaching earth or activated carbon.

Deodorization: Removing any remaining odors and flavors through steam distillation under vacuum conditions.

Winterization (Dewaxing, if applicable): Removal of waxes by cooling the oil and filtering out the crystallized particles (applicable to oils prone to wax formation, like sunflower or corn).

Each of these steps is essential in producing refined vegetable oil that meets industry standards and consumer expectations.

-

Hexane is commonly used in vegetable oil extraction, because it efficiently extracts oil from seeds. However, it is environmentally unfriendly due to its high energy requirements for recovery, its contribution to air pollution through Volatile Organic Compound (VOC) emissions, and the risk associated with its flammability and toxicity, which can harm both workers and ecosystems if not properly managed.

-

Yes! Emerging technologies like Organic Solvent Nanofiltration (OSN) membranes offer a more sustainable alternative. These membranes enhance operations while significantly reducing energy consumption and greenhouse gas emissions, making the vegetable oil refining process safer and more cost-effective.